Dried Sand: A Comprehensive Guide

Dried sand is a type of natural mineral formed from the weathering of rocks. It comes in various types, depending on its mineral composition, grain size, and moisture content.

What is Standard Dried Sand? Dried sand is sand with low moisture content, typically used in manufacturing, construction, and water filtration. Standard dried sand is river sand or quartz sand that has been dried at high temperatures to remove water, then screened to classify it into standard grain sizes.

Characteristics Dried sand has low moisture content, usually less than 1%. This low moisture content gives the sand high stability and prevents it from changing when exposed to the environment. The sand has uniform grain size, which facilitates production and construction processes. Dried sand is typically white or yellow, depending on its mineral composition.

Applications of Dried Sand Dried sand is widely used in various fields, including:

- Industrial applications: Used to protect equipment, prevent fires, spray glass, and clean metal surfaces.

- Construction: Used in the production of high-quality mortars and tile adhesives.

- Water treatment: Used in water treatment, filtering pure water and household water.

- Other applications: Used in oil filtration, industrial waste filtration, and as blasting sand for ships.

Applications by Industry

- Glass manufacturing: Dried sand is the main ingredient in glass production. Dried silica sand helps glass become transparent, shiny, and highly durable.

- Ceramic production: Dried sand is the main ingredient in ceramic production. Dried silica sand helps the glaze adhere well to the material’s surface, creating a beautiful and durable glaze.

- Water filtration: Used as a water filter material. It helps remove impurities, bacteria, and heavy metals in water, making water clean and safe for health.

- Construction: Used in construction projects such as concrete pouring, plastering, and tiling. Dried sand helps construction projects become more durable and aesthetically pleasing.

Advantages of Dried silica sand from Dương Hưng Company With many years of experience in producing and supplying various types of quartz sand and gravel, we are proud to offer our customers dried sand with the most modern drying technology. Our drying system is almost fully automated. Our products are more affordable than those dried manually. Our dried sand always meets all demands and quantities. Even in rainy weather, production is not affected. With the application of automation technology, we always meet both quantity and quality requirements. Dương Hưng Company is proud to be the first company in northern Vietnam. With many years of experience, we are a pioneer in applying machinery, technology, and sand screening. We always strive to create the best quality products at the most affordable prices.

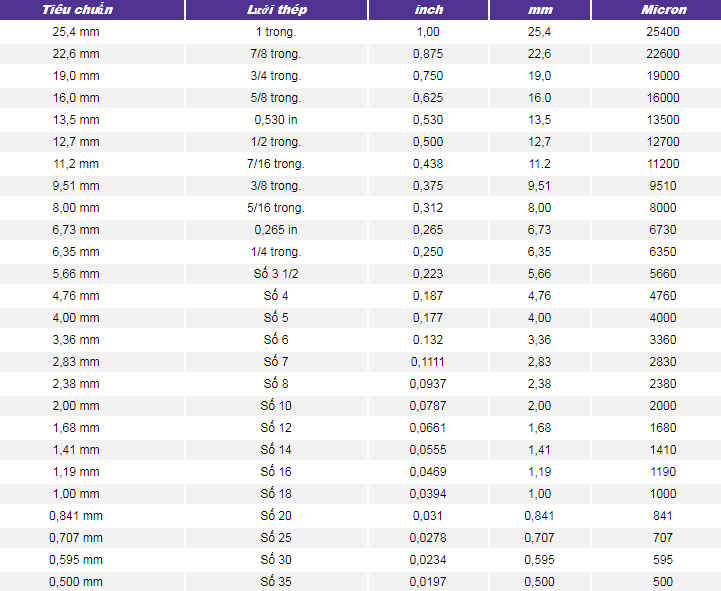

Standard Dried Sand Grain Sizes Standard Dried silica sand: 0 – 0.3mm; 0.3 – 0.7 mm; 0.7 – 1.7 mm; 0.6 – 1.2 mm; 1 – 3 mm; 2 – 4 mm; Or according to customer requirements.